Welcome to Steel Fabrication Techniques or Boosting Productivity in Steel Fabrication Workshops. In the fast-paced steel fabrication industry, maintaining productivity is crucial for staying ahead. However, achieving this goal requires more than just efficiency. It also involves prioritizing the health and well-being of the workforce.

This article explores the importance of health in steel fabrication techniques and how it can enhance productivity. By implementing strategies that promote a healthy work environment, such as ergonomic workstations and safety measures, steel fabrication workshops can minimize risks and downtime, resulting in increased output and reduced costs.

Additionally, we will delve into specific techniques, such as automation and optimized workflow management, that can further optimize productivity.

Join us on this journey to boost productivity while prioritizing the well-being of your workforce.

Key Takeaways

- Efficient steel fabrication techniques are important for increasing productivity and meeting tight deadlines.

- Streamlining processes through the use of automation technologies and lean manufacturing principles can reduce labor and material costs.

- Implementing proper safety measures and training programs in steel fabrication workshops is crucial for minimizing accidents and injuries.

- Advanced cutting techniques, such as laser cutting and CNC machines, can enhance precision, speed, and overall quality of fabricated steel products.

Common Challenges in Steel Fabrication Workshops

One of the most common challenges in steel fabrication workshops is the limited workspace’s impact on productivity. Steel fabrication requires a significant amount of space to accommodate large machinery, equipment, and raw materials. When the workspace is constrained, it can hinder the movement of workers and impede the efficient flow of materials and processes. This limitation can lead to bottlenecks, delays, and decreased productivity.

To address this challenge, workshop managers must optimize the layout of their workspace. This involves carefully planning the arrangement of machinery and equipment to maximize available space and ensure smooth workflow. Additionally, implementing efficient material handling systems, such as overhead cranes and conveyor belts, can help minimize the need for manual transportation and reduce congestion.

Moreover, investing in advanced technologies, such as computer-aided design (CAD) software and automated machinery, can further enhance productivity by reducing human error and speeding up fabrication processes. These technologies allow for precise measurements, accurate calculations, and faster production cycles.

Understanding the Importance of Efficient Steel Fabrication Techniques

Understanding the importance of efficient steel fabrication techniques is crucial for maximizing productivity and optimizing operations in steel fabrication workshops. Efficient techniques not only ensure the timely completion of projects but also contribute to the overall quality of the fabricated steel products.

Here are three key reasons why efficient steel fabrication techniques are of utmost importance:

- Increased productivity: Efficient techniques enable fabricators to complete tasks in less time, leading to increased productivity. This allows workshops to handle more projects and meet tight deadlines without compromising on quality.

- Cost-effectiveness: By streamlining fabrication processes, such as cutting, welding, and assembly, efficiency is improved, resulting in reduced labor and material costs. This helps workshops to stay competitive in the market while maintaining profitability.

- Enhanced quality: Efficient techniques focus on precision and accuracy, resulting in high-quality fabricated steel products. This not only enhances the reputation of the workshop but also ensures customer satisfaction and repeat business.

Essential Steel Fabrication Techniques for Improved Productivity

To enhance productivity in steel fabrication workshops, implementing essential techniques is crucial. Steel fabrication is a complex process that requires precision and efficiency to ensure high-quality results.

One essential technique is proper material handling. This involves using the right equipment, such as cranes and hoists, to move and position steel materials safely and efficiently.

Another important technique is accurate measuring and cutting. Utilizing advanced tools like laser cutting machines and CNC plasma cutters can significantly improve productivity by reducing errors and optimizing material usage.

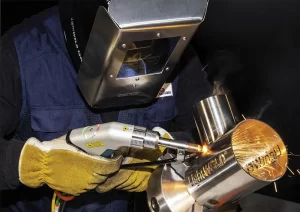

Additionally, effective welding techniques play a vital role in steel fabrication. Employing methods like MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding can enhance weld strength and quality.

Lastly, implementing lean manufacturing principles, such as streamlining processes and minimizing waste, can further boost productivity in steel fabrication workshops.

Streamlining Workflow in Steel Fabrication Workshops

To optimize productivity in steel fabrication workshops, it is essential to streamline the workflow. This involves implementing efficient processes and utilizing the right tools and technologies. Here are three key strategies to help streamline workflow in steel fabrication workshops:

- Standardize Processes: Establishing standardized procedures for each stage of the fabrication process can greatly improve efficiency. This includes creating clear guidelines for material handling, cutting, welding, and finishing. By ensuring everyone follows the same steps, errors and delays can be minimized.

- Invest in Automation: Automation technologies such as CNC machines and robotic systems can significantly enhance workflow efficiency. These machines can perform tasks with precision and speed, reducing the dependency on manual labor and increasing overall productivity.

- Implement Lean Manufacturing Principles: Adopting lean manufacturing principles, such as just-in-time inventory management and continuous improvement, can optimize workflow and eliminate waste. By eliminating unnecessary steps and reducing inventory levels, fabrication shops can operate more efficiently and respond quickly to customer demands.

Maximizing Safety and Health in Steel Fabrication Workshops

One key aspect of maximizing productivity in steel fabrication workshops is ensuring the safety and health of all workers involved. Safety measures should be implemented to minimize the risk of accidents and injuries. This includes providing proper training on handling equipment and machinery, as well as enforcing the use of personal protective equipment (PPE) such as helmets, gloves, and safety glasses.

Additionally, regular inspections of the workshop should be conducted to identify and address any potential hazards, such as faulty equipment or inadequate ventilation. It is also important to promote a culture of safety by encouraging open communication and reporting of any safety concerns or incidents.

Strategies for Boosting Productivity in Steel Fabrication Workshops

Implementing effective strategies is crucial for boosting productivity in steel fabrication workshops. By optimizing processes and utilizing innovative techniques, workshop managers can enhance efficiency and achieve higher output levels. Here are three strategies that can significantly contribute to improving productivity in steel fabrication workshops:

- Streamline workflow: Analyze the entire fabrication process to identify bottlenecks and areas of inefficiency. Implement lean manufacturing principles to eliminate waste and optimize workflow. This includes organizing workstations, optimizing material flow, and implementing standardized work procedures.

- Invest in technology: Embrace advanced technologies such as computer-aided design (CAD) software, robotic automation, and CNC machinery. These technologies can streamline design and fabrication processes, reduce human error, and enhance precision and speed.

- Continuous training and development: Provide regular training sessions to enhance the skills and knowledge of employees. This includes training in the use of new technologies and equipment, as well as cross-training to ensure flexibility and versatility among the workforce.

Frequently Asked Questions

How Can I Overcome Common Challenges in Steel Fabrication Workshops?

To overcome common challenges in steel fabrication workshops, it is crucial to implement efficient workflow processes, prioritize worker safety through proper training and protective equipment, and invest in advanced technology and equipment to enhance productivity and accuracy.

Why Is It Important to Understand Efficient Steel Fabrication Techniques?

Understanding efficient steel fabrication techniques is important because it allows for increased productivity in workshops. By utilizing the most effective methods, workers can streamline processes, reduce errors, and maximize output, ultimately leading to improved overall performance and profitability.

What Are Some Essential Steel Fabrication Techniques That Can Improve Productivity?

To improve productivity in steel fabrication workshops, it is essential to implement efficient techniques such as proper material handling, accurate measuring and cutting, precise welding, and effective assembly processes. These techniques can streamline operations and optimize output.

How Can I Streamline Workflow in a Steel Fabrication Workshop?

To streamline workflow in a steel fabrication workshop, it is essential to implement efficient processes, optimize resource allocation, and prioritize safety measures. By doing so, productivity can be enhanced, leading to increased output and overall operational effectiveness.

What Strategies Can I Use to Boost Productivity in a Steel Fabrication Workshop?

To boost productivity in a steel fabrication workshop, implementing strategies such as optimizing workflow, utilizing advanced machinery and equipment, training employees in efficient techniques, and ensuring a safe and healthy work environment can greatly enhance overall efficiency and output.

Conclusion

In conclusion, prioritizing health and implementing efficient steel fabrication techniques are crucial for boosting productivity in steel fabrication workshops.

By creating a healthy work environment and ensuring the well-being of employees, workshops can minimize the risk of injuries and downtime, leading to increased output and reduced costs.

Additionally, integrating automation, advanced cutting technologies, and optimized workflow management can further enhance efficiency in steel fabrication processes.

By combining these strategies, workshops can optimize productivity and maintain a competitive edge in the industry.

You May Also Like: