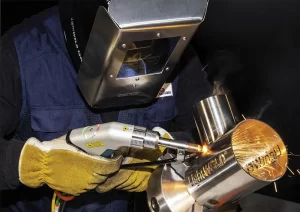

Discover the unmatched precision and efficiency of laser technology in welding, prioritizing a safer work environment. Precision welding with laser technology minimizes distortion, reduces heat-affected zones, and enables intricate designs for superior weld quality and worker safety. Proper training, maintenance, and safety protocols are essential for optimal results. Embrace laser welding solutions for improved productivity and a workplace that values precision and employee well-being. Explore the transformative impact of precision laser welding on welding practices and occupational health.

Key Takeaways

- Laser welding minimizes distortion and reduces heat-affected zones.

- Ensures superior weld quality for intricate designs.

- Enhances worker safety with focused heat source.

- Provides high accuracy in welds for complex geometries.

- Boosts efficiency in manufacturing processes with quicker speeds.

Challenges in Traditional Welding Methods

Traditional welding methods present a variety of challenges that can impede efficiency and precision in the welding process. Issues such as distortion, heat-affected zones, and weld defects are common with traditional methods. Furthermore, the need for extensive post-welding cleanup and the risk of material contamination further complicate the process. These challenges highlight the limitations of conventional welding techniques in achieving best results.

Advantages of Laser Technology in Welding

Laser technology in welding offers precision welding benefits by providing a focused heat source, resulting in minimal distortion and high accuracy in welds. The efficiency of laser welding is remarkable for its speed and the ability to join complex geometries with ease, making it a preferred choice for industries requiring high precision and productivity. These advantages make laser technology a valuable tool for achieving superior welding results in various applications.

Precision Welding Benefits

When contemplating the advantages of precise welding, it is essential to acknowledge the unmatched benefits that laser technology provides in the welding process.

- Exact control over the welding process

- Minimal heat-affected zones

- High welding speeds

- Ability to weld a wide range of materials

Efficiency of Laser Welding

Incorporating state-of-the-art laser technology into welding processes revolutionizes effectiveness by providing precise control and reducing heat-affected zones. Laser welding offers advantages such as improved speed, precision, and quality in joining materials. The focused heat source of lasers enables quicker welding speeds and narrower weld seams, resulting in increased productivity. Moreover, the minimal distortion and minimal need for post-welding finishing work boost efficiency in manufacturing processes.

Precision Welding Techniques With Lasers

Precision welding techniques with lasers involve utilizing the benefits of laser technology to achieve high levels of precision and efficiency in the welding process. These techniques encompass advanced welding methods that harness the unique capabilities of lasers to produce superior weld quality and accuracy. Laser welding offers a range of advantages, including reduced heat-affected zones, minimal distortion, and the ability to weld complex geometries with exceptional control.

Laser Welding Benefits

Using laser joining technology offers a variety of advantages in accurate welding methods, making it a favored technique for achieving top-notch, effective welds.

- Precision: Laser welding allows for highly accurate and complex welds.

- Speed: Rapid welding velocities are achievable with laser technology.

- Minimal Heat Affected Zone: Laser welding reduces distortion and damage to surrounding areas.

- Versatility: Laser welding can be used on a wide range of materials.

Precision and Efficiency

Utilizing advanced laser technology in welding processes improves accuracy and efficiency to achieve superior weld quality and performance. Laser welding allows for precise control over the energy input, resulting in minimal heat-affected zones and distortion. The focused beam guarantees concentrated heat application, leading to stronger, cleaner welds. This precision additionally reduces the need for post-welding treatments, enhancing overall efficiency in the welding process.

Advanced Welding Techniques

Laser technology has revolutionized welding processes by empowering unparalleled manipulation over heat application and ensuring precise welds with minimal distortion.

- 1. Greater Precision: Laser welding allows for highly accurate welds.

- 2. Reduced Heat Affected Zone: Minimizes material distortion.

- 3. Enhanced Control: Empowers complex weld patterns.

- 4. Increased Efficiency: Faster welding speeds owing to focused energy.

Ensuring Safety in Laser Welding Environments

Security in laser welding environments is vital for upholding a safe and productive workplace. Implementing safety measures such as proper training on laser operation, using personal protective equipment, and maintaining equipment regularly are pivotal. Controlling access to the welding area, ensuring proper ventilation, and having emergency protocols in place further improve safety. Regular risk assessments and compliance with safety regulations play a pivotal role in accident prevention.

Impact of Precision Welding on Health

The impact of precision welding on health is an essential aspect that requires thorough examination and consideration in industrial settings.

- Decreased exposure to harmful vapors and gases.

- Lower risk of breathing problems.

- Minimized chances of eye injuries.

- Reduced noise levels for better hearing protection.

Improving Efficiency With Laser Welding

How can precision laser welding improve operational efficiency in industrial applications? Precision laser welding offers a controlled heat-affected zone, ensuring minimal material distortion and reducing the need for post-welding corrections. This results in faster production cycles, decreased material waste, and improved product quality. By optimizing energy consumption and enhancing process repeatability, laser welding contributes significantly to streamlining operations and maximizing efficiency in various industrial settings.

Future Trends in Precision Welding Technology

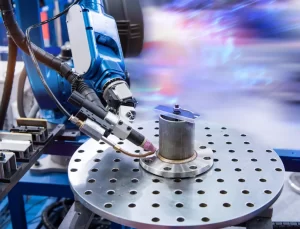

As industries continue to adopt precision laser welding technology for improved efficiency, it is vital to investigate the evolving scenery of forthcoming trends in this advanced welding methodology.

- Increased Automation: Integration of AI and robotics for advanced precision.

- Advancements in Monitoring Systems: Real-time data analytics for quality control.

- Enhanced Connectivity: IoT integration for seamless communication between systems.

- Eco-friendly Practices: Development of sustainable welding technologies.

Frequently Asked Questions

How Does Laser Welding Technology Compare to Traditional Welding Methods in Terms of Precision and Efficiency?

Laser welding technology offers superior precision and efficiency compared to traditional methods. Its focused heat source allows pinpoint accuracy, reducing distortion and heat-affected zones. The automated nature improves consistency and speed, making it a preferred choice for complex and high-volume projects.

Are There Specific Safety Measures That Need to Be Taken in Laser Welding Environments to Ensure the Well-Being of Workers?

In laser welding environments, specific safety measures are essential to safeguard workers’ well-being. These include proper training in handling equipment, ensuring adequate ventilation, using appropriate protective gear, and implementing regular maintenance checks to minimize hazards and maintain a healthy work environment.

What Are Some of the Potential Health Benefits Associated With Precision Welding Using Laser Technology?

Precision welding with laser technology offers health benefits such as reduced exposure to fumes and toxins, improved air quality, and enhanced safety because of minimized heat-affected zones. These factors contribute to creating a healthier work environment for operators.

How Can Laser Welding Improve Overall Efficiency in the Workplace Compared to Traditional Welding Methods?

Laser welding improves workplace efficiency by providing precise control, minimizing material waste, and reducing production time. Its non-contact nature reduces distortion, ensuring high-quality welds. Advanced automation features further streamline processes, leading to increased productivity and cost-effectiveness compared to traditional welding methods.

What Are Some Upcoming Trends or Advancements in Precision Welding Technology That We Can Expect to See in the Future?

Advancements in precision welding technology are poised to revolutionize the industry. Anticipate developments such as improved automation, increased integration of AI for process optimization, and the utilization of inventive materials to boost performance and efficiency in laser welding processes.

Conclusion

In e, the integration of precision welding with laser technology offers significant advantages in improving workplace environments. By enhancing efficiency, safety, and overall health outcomes, laser welding techniques contribute to a more sustainable and productive industrial e. The synergy between advanced technology and workplace well-being underscores the importance of embracing innovative solutions for fostering healthier work environments. As precision welding technology continues to evolve, the future trends in this field e for further enhancing workplace conditions.

You May Also Like: